INTRO

When I need leather for craft purposes searching for proper type comes out in-to whole adventure. There are so many types of leather. Some types were defined historically, some were invented over time. It is painful to understand this, and the search here is not even by touch, because... you can't touch retouched photos or controversial description. As a result - complete random even where I expected something specific.

So, in this article I will collect the terminology of leather as a material for crafting.

CONTENT

Even when you can clearly characterize the type of leather with the help of terminology, you should understand that the general process may differ here and there depending on the company that produces the leather, because each has its own secrets that somehow affect the final result.

Anyway, to begin with, you need to understand what the leather manufacturing process consists of:

Preparatory stages

A complex, multi-step process in which the skin is prepared for further processing. At this stage, all redundant is removed: hair, remnants of flesh or fat, and only bare hide/skin remains. This is a mandatory general stage, which can be performed in different ways, but the output effect is the same and therefore it is almost not interesting in terms of determining the skin type. The only thing that can be significantly different here is the skin of which animal is used as a basis. Also if to stick to terminology "hide" is for large animals and "skin" is for smaller ones.

Tanning

At this stage, the prepared hide/skin soaking and saturated with tannins. This is needed to stabilize, protect against bacteria and increase the durability of the skin.

Vegetable tanning:

A classic method using natural vegetable tannins. This was done like this long from long time ago when there were no other options. But this method takes much more time and is generally more laborious so as a result very expensive for mass production. Of course, there are companies that remain devoted to traditions, but the result of their work is almost much more expensive for the final buyer. At the exit, the skin has a unique appearance. The color depends on the plant from which the tannin was used. The coloring is not uniform. Texture is prone to the effect of aging and patination. The appearance of a product made of such leather becomes nobler over the years.

Chrome tanning:

A modern method using chromium as a tannin. It gives a much faster and more consistent result for less. Therefore, mass production uses this method. The skin after it looks more standardized. The color is bluish gray. Over time, it does not show obvious signs of aging and therefore resembles synthetics, but, of course, retains the properties of natural leather.

Crusting

In general, over time, this stage lost a clear boundary with the previous one. At this stage, the skin is dried, stabilized and conditioned and given properties for its further purpose.

Cutting in to sections:

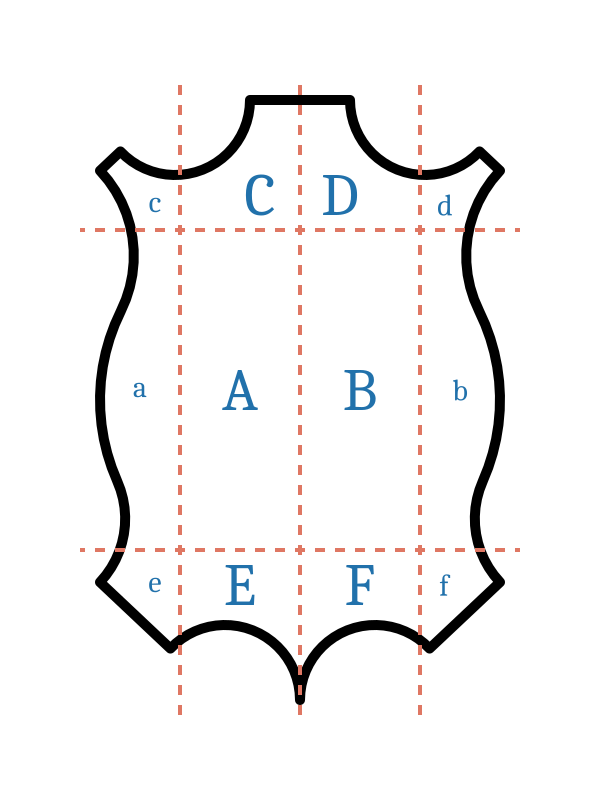

Different sections of hide/skin has different properties so sometime it's important to know which part you are working with. Global naming and example in search results are absurdly diverse but I found few resource with most complete description of this mess.

Redrawing it in good quality and attaching here.

Whole Hide: (A + B + C + D + E + F + a + b + c + d + e + f)

Side (A + C + E + a + c + e) , (B + D + F + b + d + f)

Bend: (A + E) , (B + F)

Double Bend: (A + E + B + F)

Shoulder: (C + c) , (D + d)

Double Shoulder: (C + c + D + d)

Butt: (E + e) , (F + f)

Double Butt: (E + e + F + f)

Belly: (a + c + e) , (b + d + f)

Double Belly: (a + c + e + b + d + f)

Foreshank: (c) , (d)

Hindshank: (e) , (f)

Single cut: (A + B)

Splitting in to layers:

The structure of the Genuine Leather is heterogeneous and is divided into layers depending on the fiber density:

Skin > Grain > Grain & Corium Junction > Corium

By splitting hide in different intersections of this layers we can get different types of leather:

Full Grain = Skin + Grain + 1/2 Grain & Corium Junction

Split = 1/2 Grain & Corium Junction + Corium

Top Grain = Grain + Grain & Corium Junction + 1/2 Corium

Genuine = Corium

Additional manual processing:

Shaving - additional process of thinning leather by cutting fibres off.

Buffing - abrasion of the surfaces of the leather to reduce nap or grain defects.

Softening - physical softening of the leather by separating the leather fibres.

Additional chemical processing:

Adjusting leather moisture level in various ways. Neutralization of the leather pH level.

Retanning leather with additional tanning agents to impart properties. Stripping off superficially fixed tannins.

Fixation of unbound chemicals or removing them from the leather.

Dyeing:

Adding colorant during tanning process to soak leather with it - not just paint outer surface.

Adding additional components:

Fat-liquoring - fats, oils, waxes are used to fix leather fibres.

Stuffing - fats, oils, waxes are added between the fibres.

Filling - filling leather fibres structure with dense and heavy chemicals to make the leather harder and heavier.

Surface coating

Finnish step when outer surface of the leather additionally processed to achieve various properties. There are too much of them so I just put a list from WiKi here.

brushing

polishing

padding

plating

embossing

ironing

roller coating

curtain coating

oiling

spraying

buffing

impregnation

glazing

combing

CONCLUSION

As you can see, the biggest problem in the leather selection process is that despite the fact that the basic process is the same everywhere, each manufacturer has its own additional specifics and secrets. Leather production is directly related to the fashion industry and therefore the level of snobbery here is off the charts.

Unfortunately, even with a clear understanding of the terminology, you may come across something that is not what you expect. But at least I hope I managed to clear up the basics.

Going to add more illustration here.

Created by TennojiM

All rights reserved

© 2025

All rights reserved

© 2025