I decided to start my trackball journey with the most safe choice on the market, and this is "Kensington SlimBlade Pro".

This trackball is symmetrical, index controlled, static, 52mm model.

At first, I preferred to hold my hand over it, but once I got used to this kind of device, I tried some simple wrist rest. Just because solid wrist rests are not adjustable, there was some feeling of limitation in my hand. In the end, I took a fiber cloth, folded it a few times for comfortable height, and I can say it's the most comfortable wrist rest I ever used.

This trackball has two sensors in the ball socket. One for movement and one for scrolling. Using the knob movement of the trackball for scrolling feels super cool. At first, you are using a glossy finger guiding ring around the rolling ball, but after some time, you are intentionally starting to scroll by rotating the top of the rolling ball with three fingers.

The biggest problem with static moving mechanisms is... well, actually, friction itself. The resistance that can be felt at the moment when you start moving the ball from a rest state is called "stiction". Even considering that the point of contact between three bearing balls and a rolling ball is close to none, this factor can significantly affect stiction:

Viscosity of the lube coating;

Bearing balls wearing resistance;

Rolling ball material density;

Lube coating

Eventually, all trackball owners face the situation when they need to clean the trackball, and after wiping the rolling ball with isopropyl alcohol or washing with soap in warm water, the mechanism stops sliding completely. Of course, the first thought is that you broke the thing, but it is not like this. On forums and in thematic topics on Reddit, users are advised to rub the rolling ball against the forehead or the top of the nose. Yes, it really works, but our body fats are more suitable for natural lubrication of the rolling ball during interaction, and to fully restore the gliding function, it is better to use lanolin. This is a natural fat obtained in the process of boiling sheep's wool. Apply a bit to a rolling ball, rub on the surface, wait a bit, and then wipe off the residue with a dry tissue. After this, your device supposes to return all gliding functionality.

I also tried vaseline, neutral machine oil, PTFE lube, and all of them work only temporarily by providing a high amount of gliding but eventually increasing the level of stiction. The best of all, and safer, is still 100% lanolin.

Bearing balls replacement

After some time of usage, almost any types of bearing balls will wear out. So I decided to replace the original bearing balls with a silicon nitride version, which has a self-lubricating effect. I bought some with G5 precision. The overall process of replacing them is fairly simple if you are familiar with the disassembly of the small electronics. Here are some main steps:

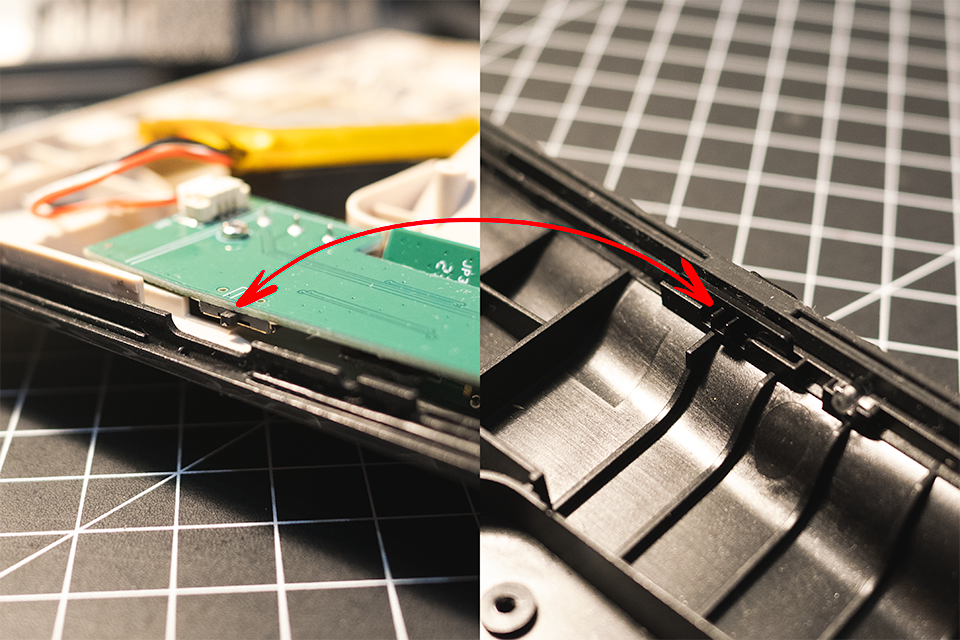

Firstly, we need to open the case. The screws are hidden behind the rubber feets. Here is the marking, where. There is no need to peel off the rubber feets completely, but you can slightly raise them from the edge. After unscrewing all 7 screws, carefully walk along the seam with a plastic mediator to release internal latches. Thereafter, the case should open like a shell.

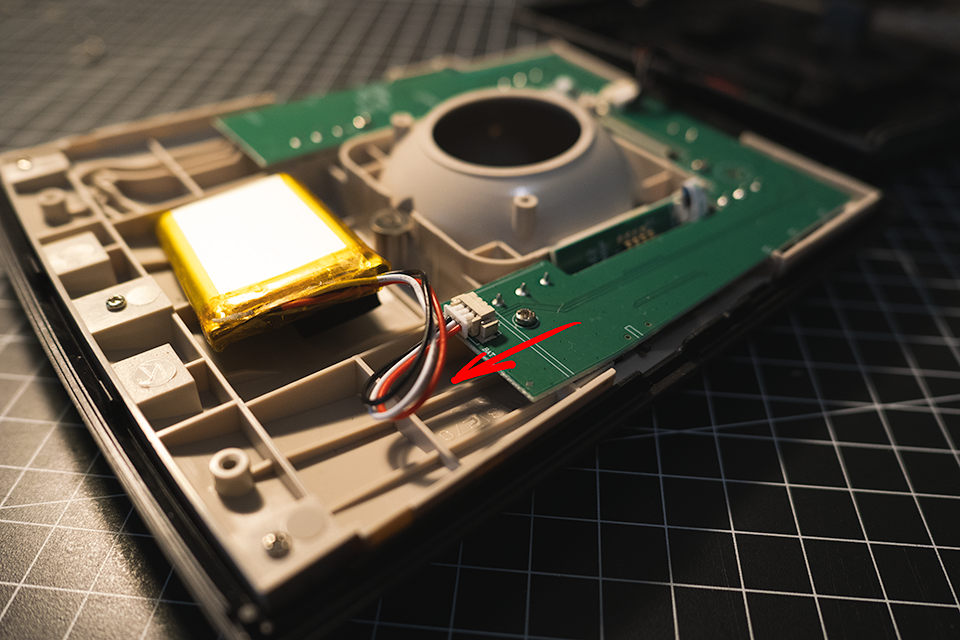

Disconnect the battery.

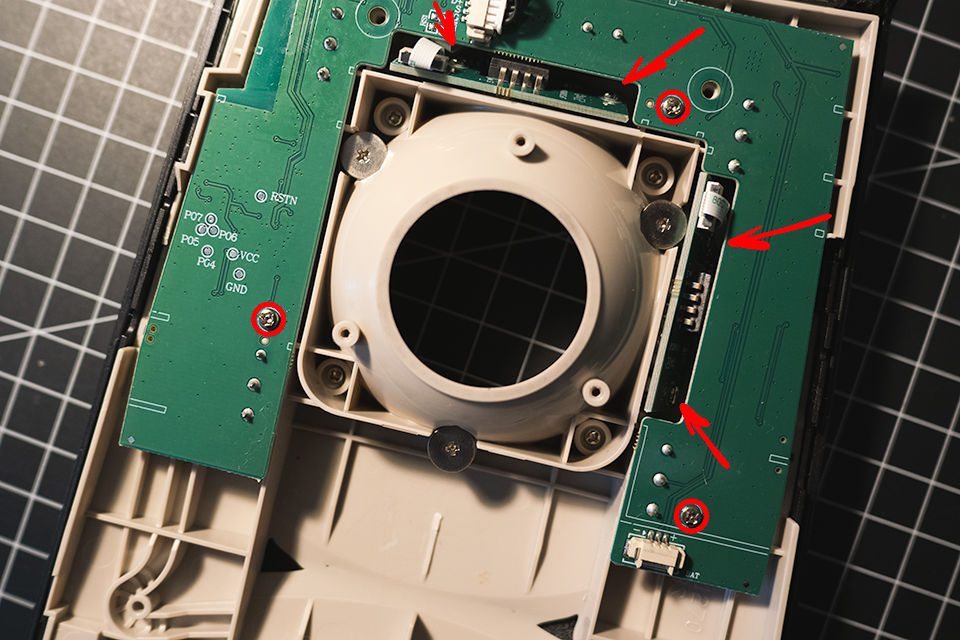

Unscrew the main board. The screws are marked with circles. Since I would rather not deal with fragile flex cables, after carefully lifting the main board, I unscrew two boards with sensors. The screws are marked with arrows.

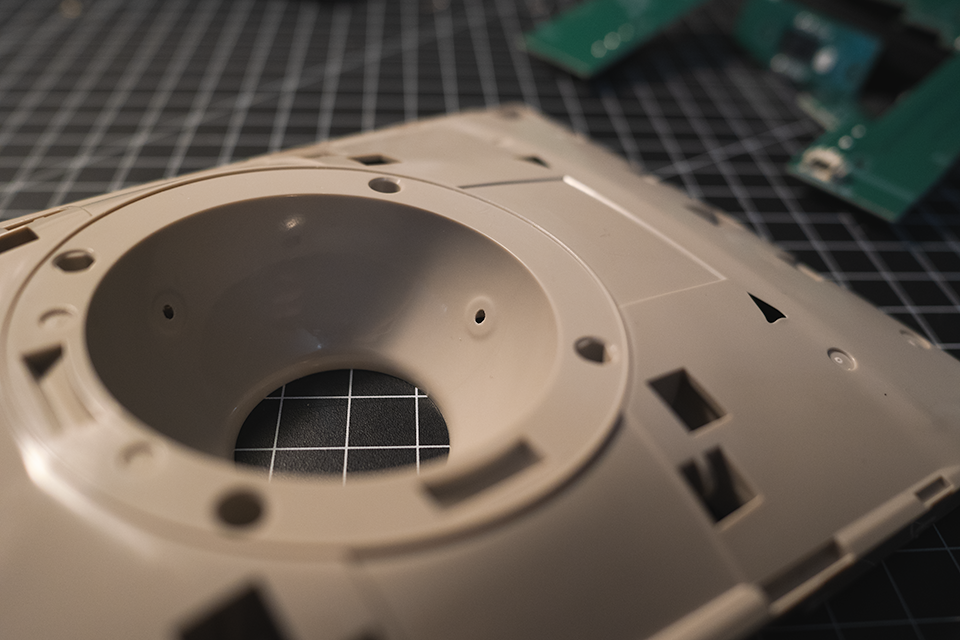

The sensor boards are aligned by two positioning pins, so it is difficult to mismatch their positions. If you put the board correctly, it is difficult to mismatch the position of the lenses as well, but it is better to remember their orientation and carefully put them aside. Now, electronics don't bother us.

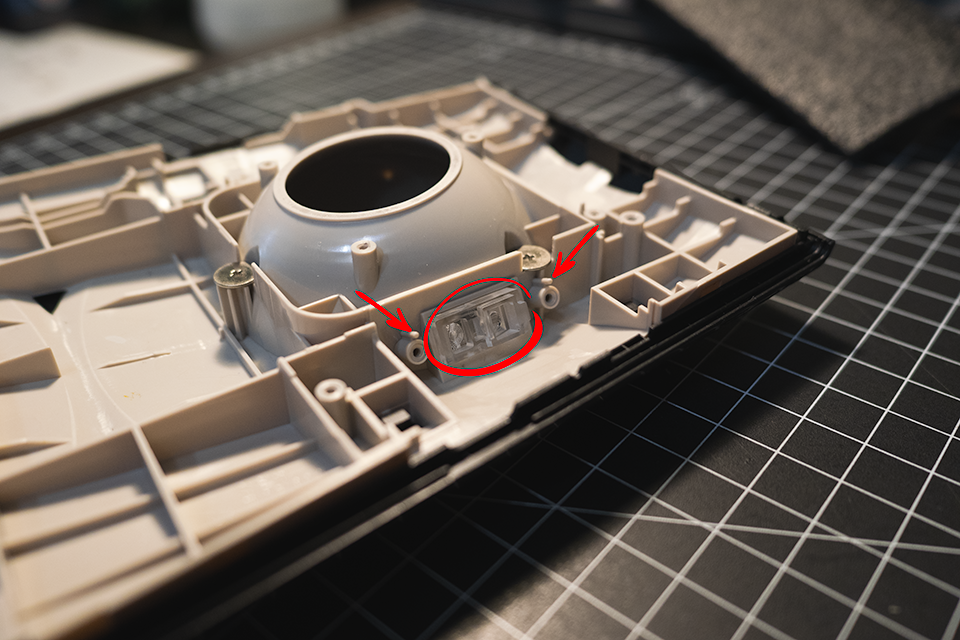

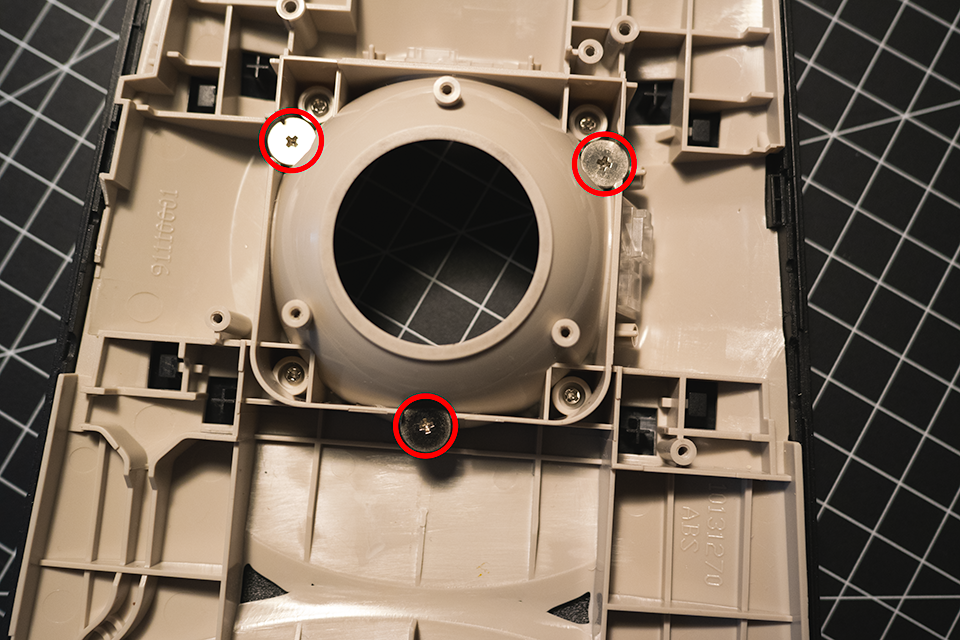

After unscrewing the three clamping screws, we finally get access to the bearing ball sockets.

Now we can push out bearing balls from their sockets with a thin picking tool. Insert this tool into each hole from the side of the rolling ball socket and catch old bearing balls from the side where the clamping screws were. Now let's clean bearing ball sockets by rinsing them with isopropyl alcohol. I also decided to expand bearing ball socket holes from the rolling ball side to make bearing balls stick out a bit more.

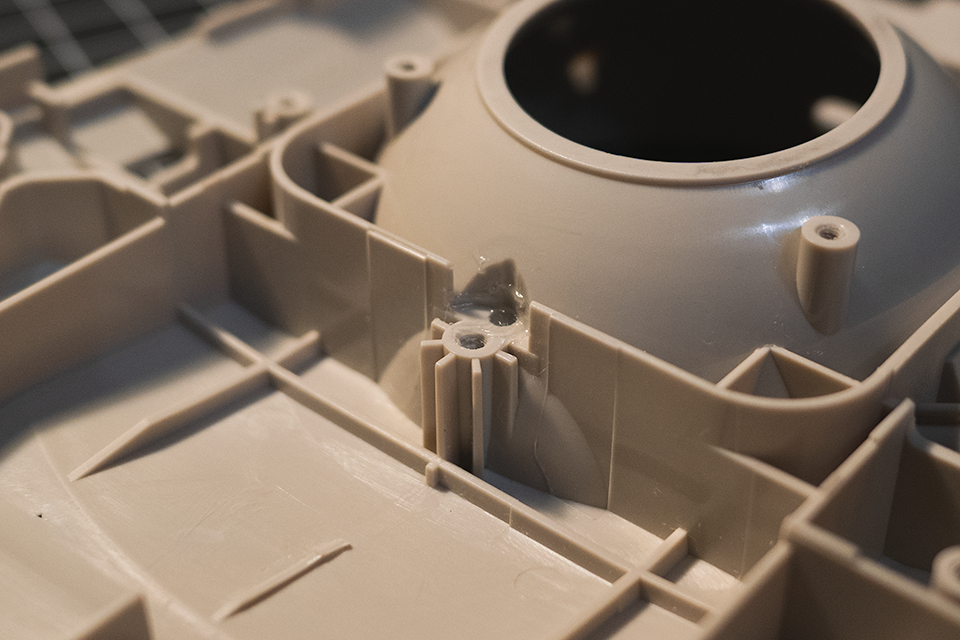

During this process, I packed bearing ball sockets with "Super Lube" grease. In theory, such a trick is supposed to help with constant lubrication of the points of contact with the rolling ball. Furthermore, it helped to keep bearing balls in place for the period of assembly.

Now it is time to grab replacement bearing balls.

Put new bearing balls in the sockets and screw the clamping screws back.

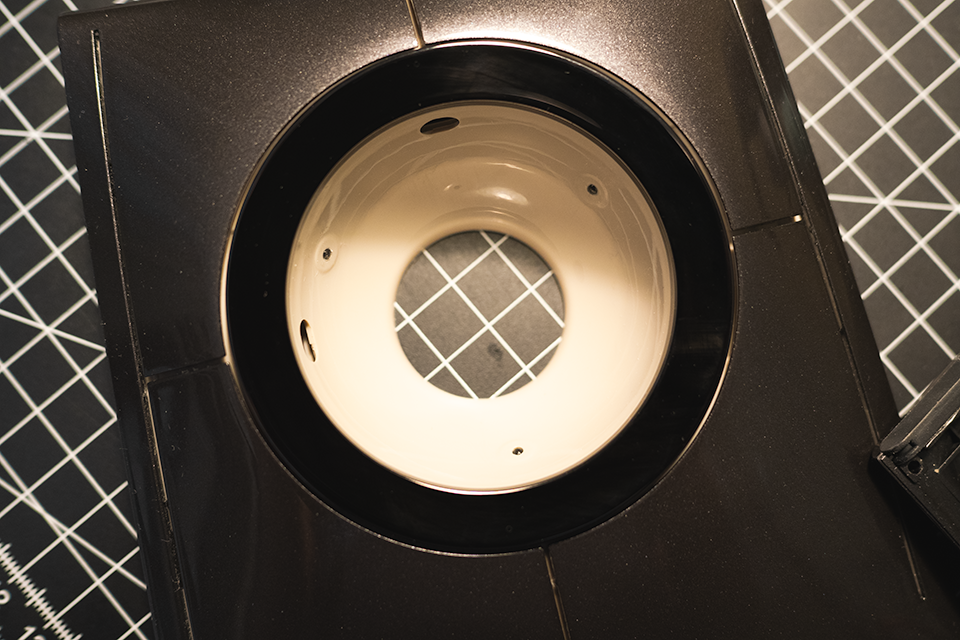

Do not mind that on the photos I have the upper part of the case completely disassembled. The finger guide ring was installed incorrectly at the factory. A gap from an uneven fit drove me nuts and also slightly skewed the whole assembly. I had to fix this. As you can see, now the seam between the ring and the inner part of the case is visually even and not perceptible by touch.

Now we can put it all back together in reverse order. Pay attention to the alignment of the control elements, especially the connection mode switch.

Wipe the ball with lanolin, and that is it. Better than new.

Rolling ball material

For the current revision of "Kensington SlimBlade Pro" many users have complaints regarding the material of the rolling ball. For some reason, it feels a bit rubbery. I made a purchase recently and can confirm it. Because of this, some users are buying third-party balls for replacement. I also tried to do so. Here is the demo with Perixx PERIPRO-304 ball.

Long story short, it is making a slight difference. Not much because the stiction effect will always be presented in trackballs with static ball moving mechanism. Also, I felt a bit of scratchiness in alternative ball. So decide for yourself if it is worth replacing the original ball with an alternative one.

Version: 2025_05_15_000002

Created by TennojiM

All rights reserved

© 2025

All rights reserved

© 2025