Now there is a boom in CNC technologies, but I keep manual version of Sherline lathes and milling machine for studying fundamental processes and for hobby reasons. The biggest frustration when working on manual machines comes when you need to do repetitive manual interaction, in particular - turning the damn hand-wheels. Some time ago I thought that this problem was an exaggeration. Oh how wrong I was. When you have to make many long distance passes, calluses appear over time and your hands begin to fall off. I know that this is a problem not only with miniature watchmaker machines, but also with bigger tabletop machines and even huge workshop giant machines.

I have seen how people solve this problem by making special screwdriver adapters to turn the hand-wheels with them. And I decided to design my version, but with the possibility of unification for the needs of others.

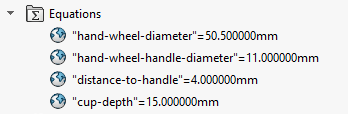

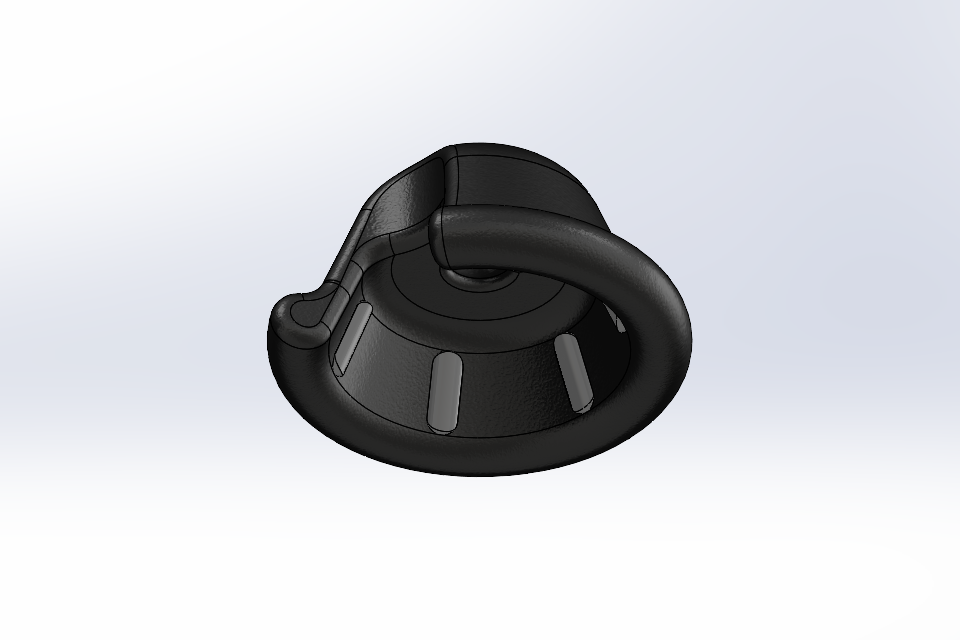

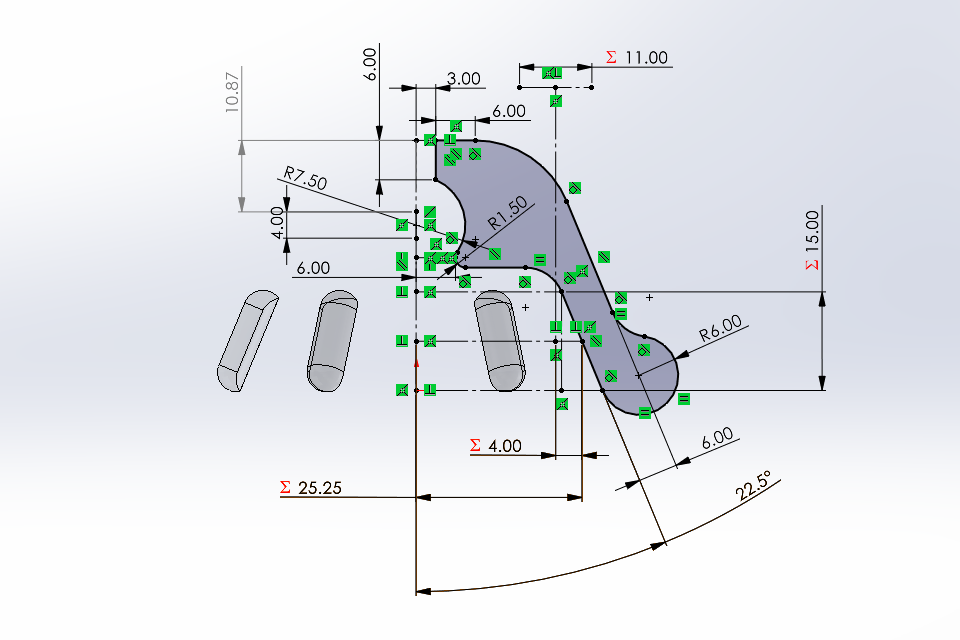

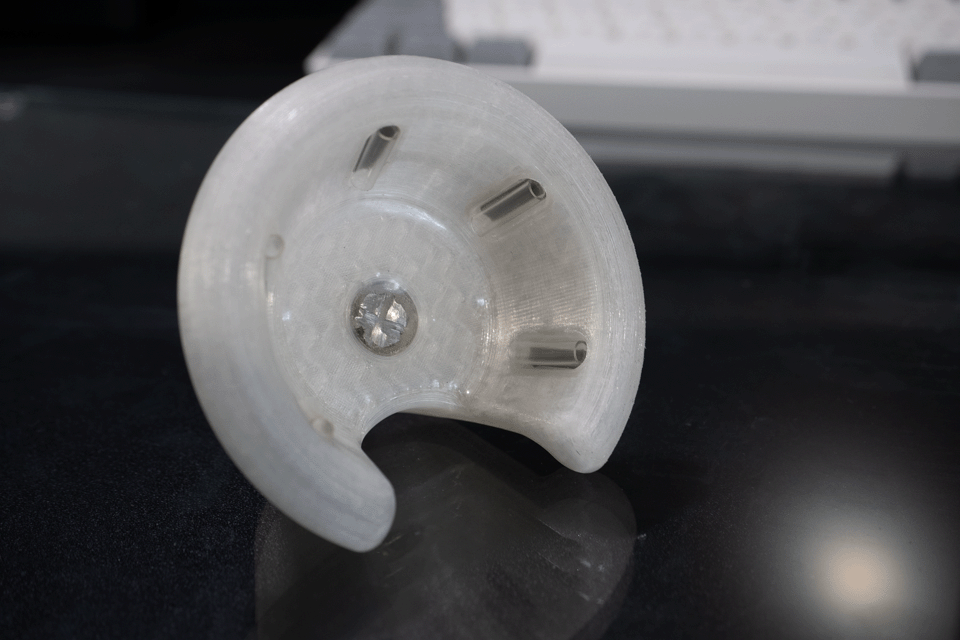

Here's what I got. This model is completely parametric, which means that key parameters in it can be changed. Radius of the hand-wheel, diameter of the hand-wheels handle, distance from the edge of the hand-wheel to handle is the prioritized parameters. Also you can change depth of the bowl. By adjusting these parameters in "Equations", you can get a cup for your type of hand-wheel.

The part itself designed to be printed on FDM printer.

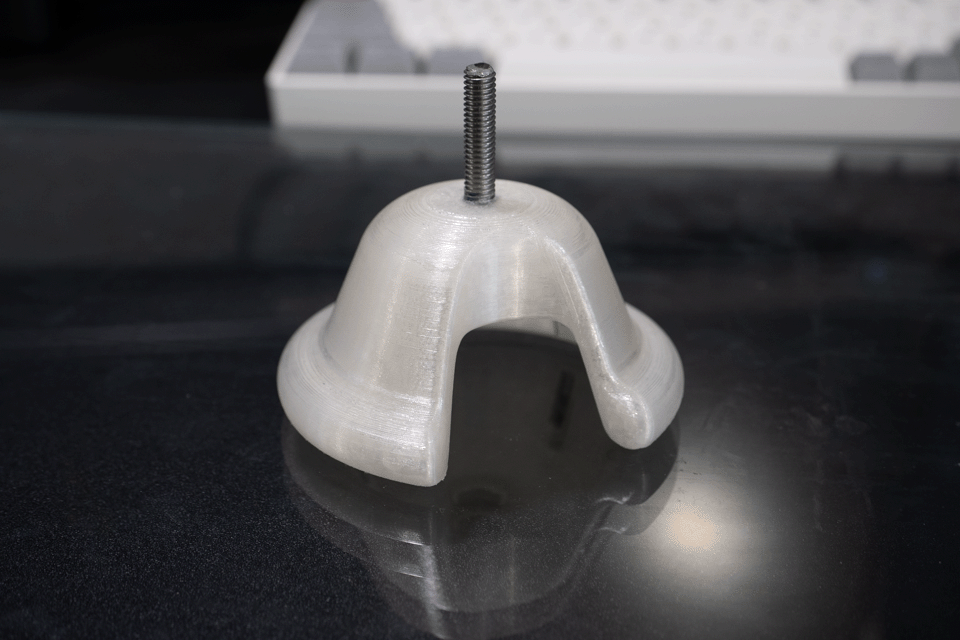

As for the shank we are going to use Stainless DIN933 M6 bolt. In the model we have special place where bolt head goes.

Afterwards this place filled with resin and you get some type of infusion of metal bolt into 3D printed part. I made additional aligner block to keep bolt straight during resin curring process.

It is also important to make the surfaces of the bolt that will be in contact with the resin rough and serrated. I am using portable andle grinder with metal cutting disc to sand surfaces and do some cross cuts here and there. It is increasing the contact surface area and make adhesion much more stronger. Do not forget to wipe bolt with acetone to degrease surfece.

1/6 of the circle if for the cut for the handle. 5/6 of the circle has slots for grippers. In the model I made gripper with particular shape with thoughts to make them from silicone. But I am still in research of most suitable solution here. In theory any grippy, squeezable material with good wear resistance will fit. For now I just glued some PVC tubes there and they are work surprisingly fine.

Here you can find

CAD model.

And here you can find

STL files compiled for smaller Sherline handwheel.

Will think about grippers a bit more. But even now it all works surprisingly well.

Here some demo of how it works.

Created by TennojiM

All rights reserved

© 2025

All rights reserved

© 2025