Ukraine

history

diy

guide

software

art

review

hardware

shortnote

animation

manga

media

learning

cad

3d

tool

mobile

android

gaming

programming

automation

drawing

compilation

millitary

movie

horror

design

vector

material

leather

information

digital

photo

SUBMIT

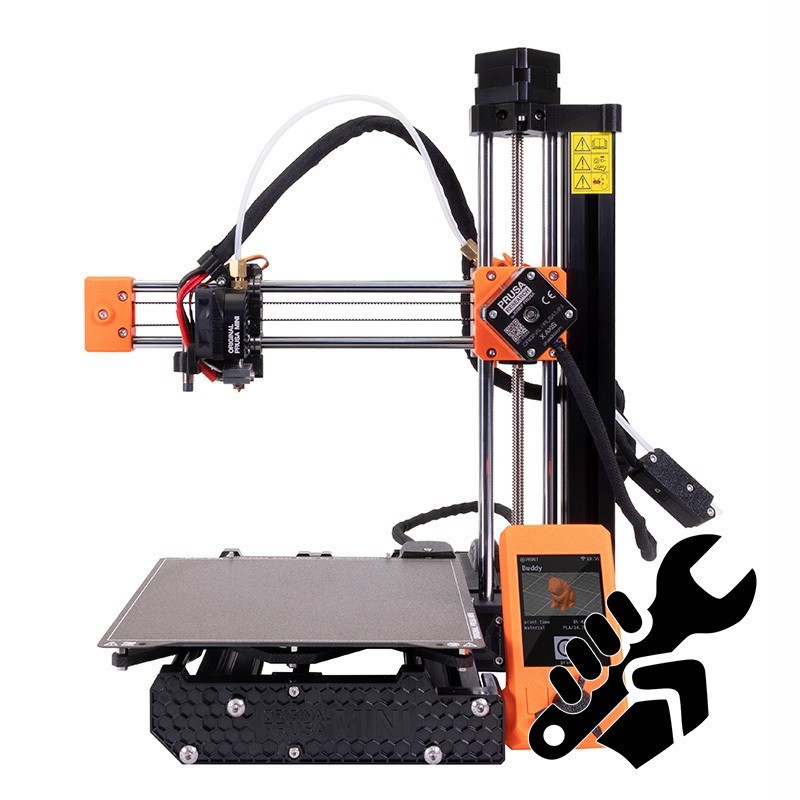

Aside from my past experience with FDM 3D printing, which was more of a pain than a pleasure, since i bought "Prusa Mini +", those emotions have changed dramatically. I finally see great example of FDM 3D printer that prints good out of the box, and the option to buy it as a "kit" format and assemble it piece by piece gives a complete understanding of the design and removes the fear of modifying this design. So... what I am doing. This article will be the list of my mods for "Prusa Mini +".

Read more inside!

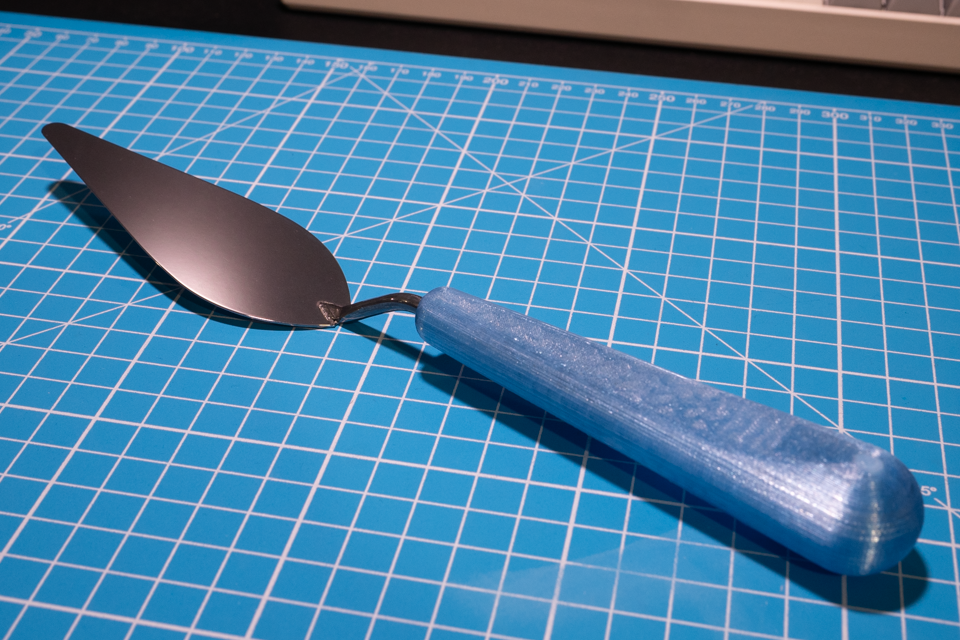

Long story short. In both types of 3D printing time to time you need some tool assistance to peel off a part from the building surface. And it is painful to watch how users are using sharp cheap scraper that usually comes with the 3D printer. It is easy to scratch built surface, easy to damage part and so easy to cut yourself accidentally.

But I found great alternative and make it even greater.

Read more inside.

Somer time ago I mentioned there that I want to create my unique design of machine for recycling PET bottles in to 3D printing filament. There are plenty designs from other enthusiasts available online. However I want to create most compact and simple one.

And long story short I have a success in it. The article will be updated with the project progress.

Read more inside.

Here is some video demo.

Sometimes, when you crafting something, you need to have a surface that is guaranteed to be flat. Huge cast iron or granite plates are definitely overkill for hobby purposes. The best option that any enthusiast can find is simple thick glass made by float technology. Such glass has a perfectly flat surface without distortions. This is more than enough to have a work surface which you can use as reference during crafting or assembling process.

So i modeled custom 3D printable corner legs for it.

Read more inside!

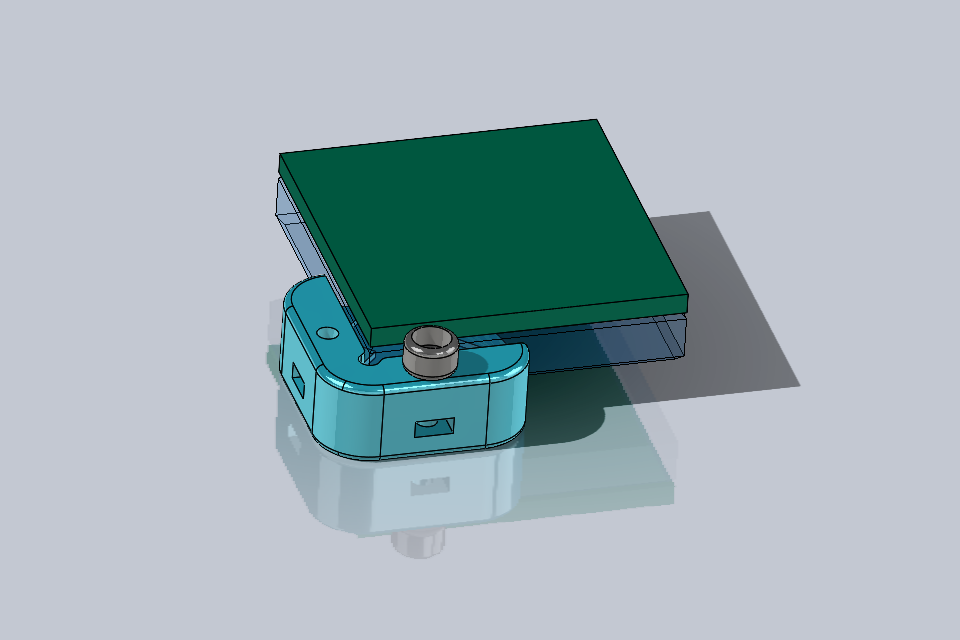

Recycling materials by the efforts of each individual is a great thing. One of the efficient ways of recycling is recreation of PET bottles in to 3D printing filament. Amount of such machines design grows. I am waiting for some hardware to build my own variation. And while I am waiting I decide to create my version of PET bottle cutter.

After 3 full iterations and even more intermediate designs that were rejected at the CAD stage, I achieved an effective result.

Open article for more.

Now there is a boom in CNC technologies, but I keep manual version of Sherline lathes and milling machine for studying fundamental processes and for hobby reasons. The biggest frustration when working on manual machines comes when you need to do repetitive manual interaction, in particular - turning the damn hand-wheels. Some time ago I thought that this problem was an exaggeration. Oh how wrong I was. When you have to make many long distance passes, calluses appear over time and your hands begin to fall off. I know that this is a problem not only with miniature watchmaker machines, but also with bigger tabletop machines and even huge workshop giant machines.

I have seen how people solve this problem by making special screwdriver adapters to turn the hand-wheels with them. And I decided to design my version, but with the possibility of unification for the needs of others.

Here's what I got. Open full article for more information.

Created by TennojiM

All rights reserved

© 2024

All rights reserved

© 2024