Long story short. In both types of 3D printing time to time you need some tool assistance to peel off a part from the building surface. And it is painful to watch how users are using sharp cheap scraper that usually comes with the 3D printer. It is easy to scratch built surface, easy to damage part and so easy to cut yourself accidentally.

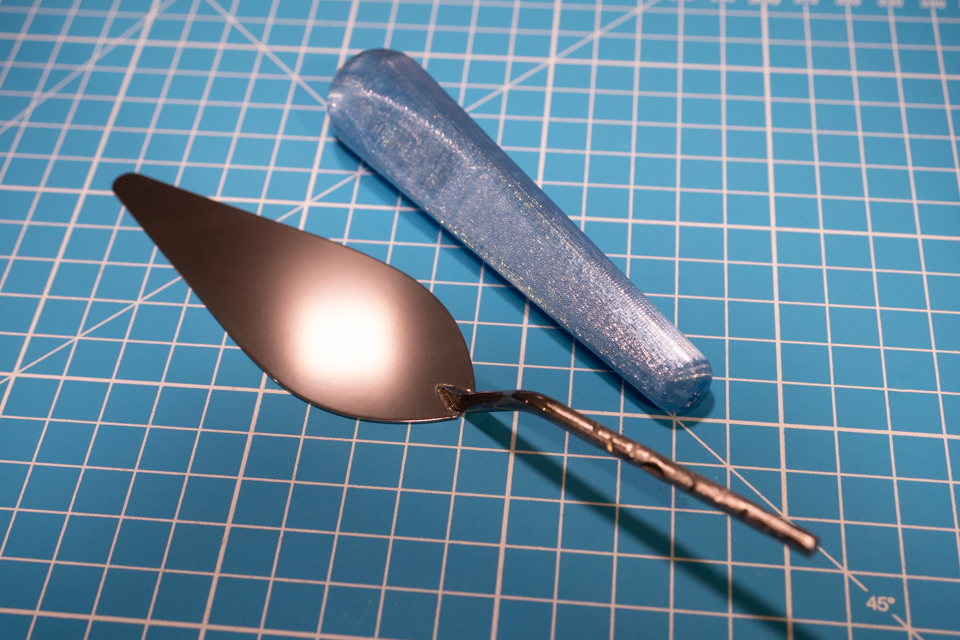

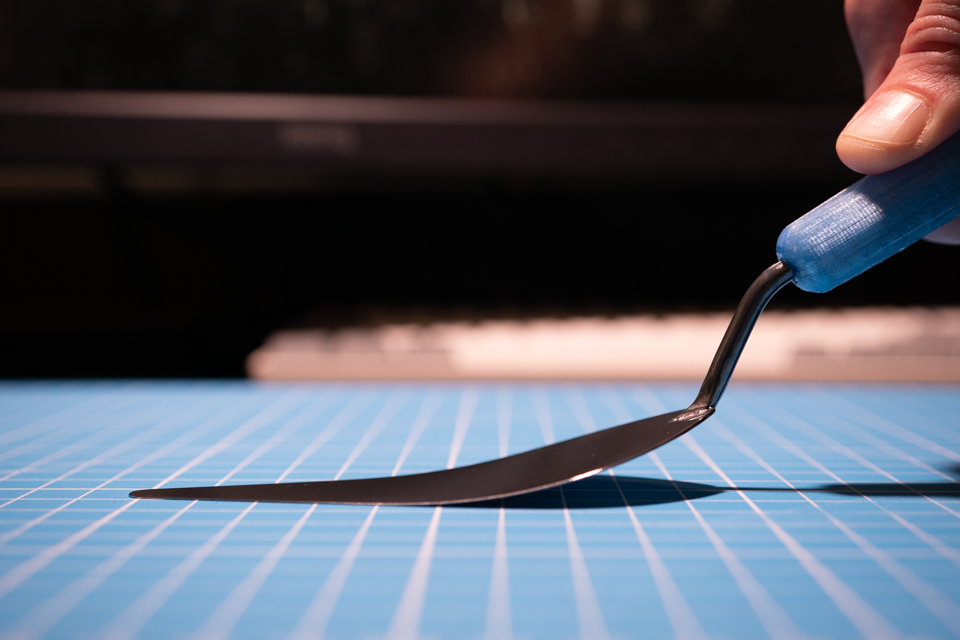

But I found great alternative that you can buy in... art supply store. This small tool for oil painting that comes in different shapes and sizes called mastihin. It is made from stainless spring steel so it's not rusting and very flexible. Spatula is thin and because of curved crowbar like connection to the handle it is pretty easy to pry up the edge of detail and crow under it flush to the build plate surface. And the most important thing that edges of spatula are rounded so it is impossible to cut yourself or scratch built surface with it even with direct cutting movement.

Only one downside of this tool that it comes with wooden handle covered with varnish which dissolves with isopropyl alcohol pretty actively. Also its shape not the best for scraping movements... this is tool for art, after all.

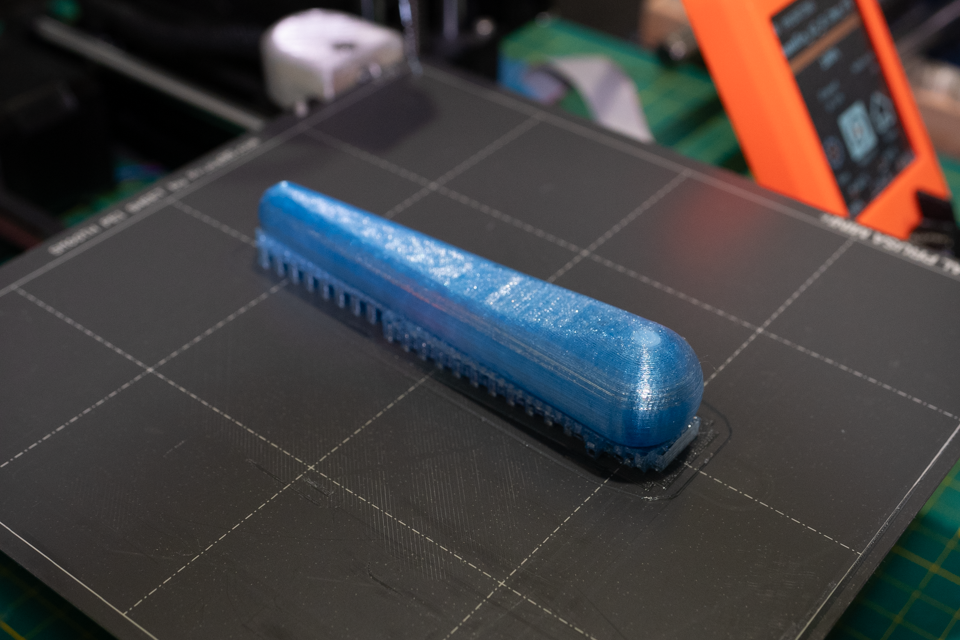

So I designed alternative 3D printable version of handle.

Shape is comfortable for scraping movement.

Ergonomic curve provide perfect spot for thumb.

I made tail hole deeper from 30mm to 50mm to locate hand grip closer to spatula part.

Also inner surface of the tail hole has waved shape to reliably infuse metal spatula tail inside with epoxy resin and made handle and spatula parts into one solid structure.

Now I can got rid of original handle. I filed out fixation ears with flat file and made spatula part tail roundly shaped along the entire length that will be glued-in inside handle. After this I sanding this surface roughly with the same file for better adhesion and in addition made deep caverns here and there with triangular file for stronger fixation during epoxy resin infusion.

After this I took acetone and wiped-out protective lacquer from spatula surface and also degreased glued-in surface of the tail with it.

Now spatula part is ready to be infused in to handle part with simple 2 to 1 epoxy resin. But how to fill a deep and narrow hole with resin from the very bottom? Here I designed simple funnel straw that can easily be printed in spiral vase mode.

As you can see, it's easily fit inside hole and makes the resin pouring process much easier. Once resin is mixed you need to pour it to the top cup and then slowly pull out funnel straw for just a bit and wait for resin to pass through. Repeat the procedure few times until the hole is half filled with resin.

Now fix handle with glued-in spatula in vertical position and wait for the resin to cure.

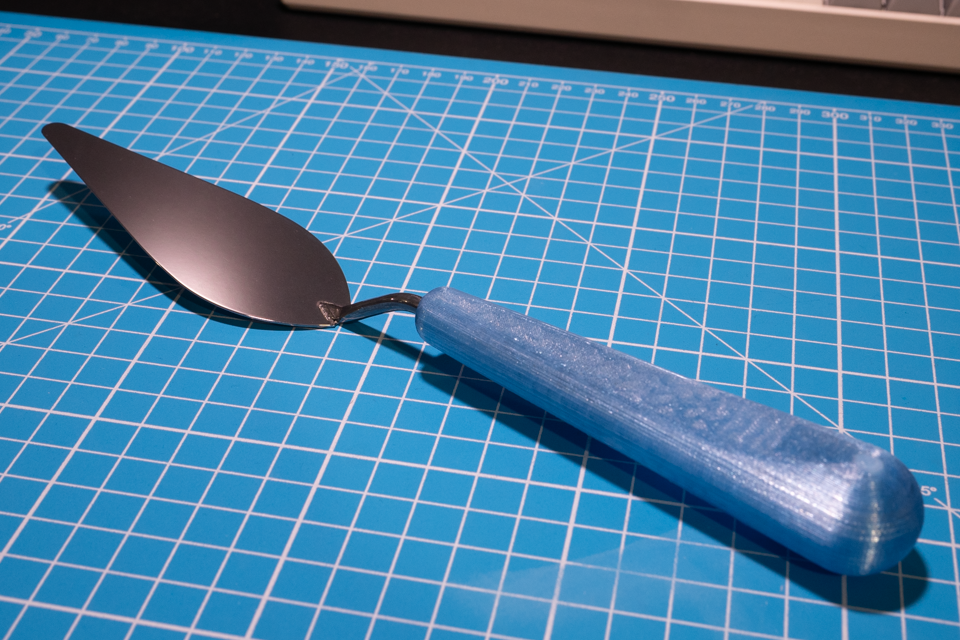

And here what we get in the end. I think looks cool.

Check how flat it lays on the surface and can be pushed right under the part that need to be dismounted from the built plate.

And that is it. Keep your built surface and your hands safe.

Created by TennojiM

All rights reserved

© 2025

All rights reserved

© 2025